ADW released its first self-developed piezoelectric dispensing valve on site, and its industrial precision control series products such as piezoelectric stacks and ultrasonic motors made their debut at an overseas exhibition.

On June 11, SENSOR+TEST 2024 officially opened. ADW released lead-free ceramic sensors on site. The first self-developed piezoelectric dispensing valve, piezoelectric stack and other new products were unveiled on the same stage, attracting widespread attention.

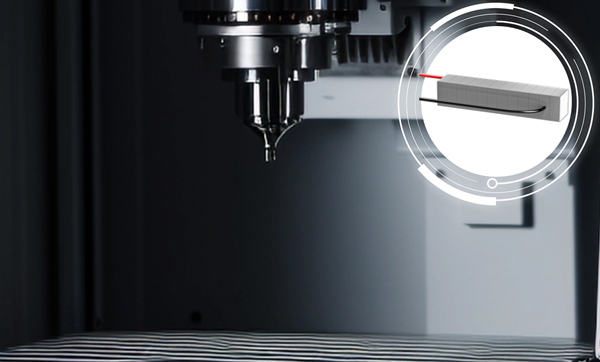

Piezoelectric stack's overseas debut

Piezoelectric stack is a multilayer piezoelectric ceramic formed by hot pressing, bonding and co-firing multiple piezoelectric ceramic films. It uses the inverse piezoelectric effect to convert electrical energy into mechanical energy. The product has the advantages of high resolution, high-precision displacement, fast response speed, small size and high output. It is widely used in high-precision valve control, micro-displacement control consoles and other fields.

Piezoelectric technology improves industrial production efficiency and yield

Industrial equipment that uses piezoelectric stacks as core control elements can precisely control valve opening and closing through tiny differential displacement movements, achieving non-contact, stable and precise output. For example, piezoelectric dispensing valves take advantage of their technical advantages. The piezoelectric stack can quickly respond to the open and closed states, achieve fast fluid injection switching, and achieve fast response and precisely controlled injection actions, thereby improving production efficiency and product qualification rate.

Micron-level displacement lifting equipment with high operating accuracy

The piezoelectric stack generates deformation displacement through the inverse piezoelectric effect, and its displacement motion can be as small as micron level. The control valve using this product can control the output of the colloid injection volume within a microcubic volume, thereby improving the operating accuracy of industrial equipment.

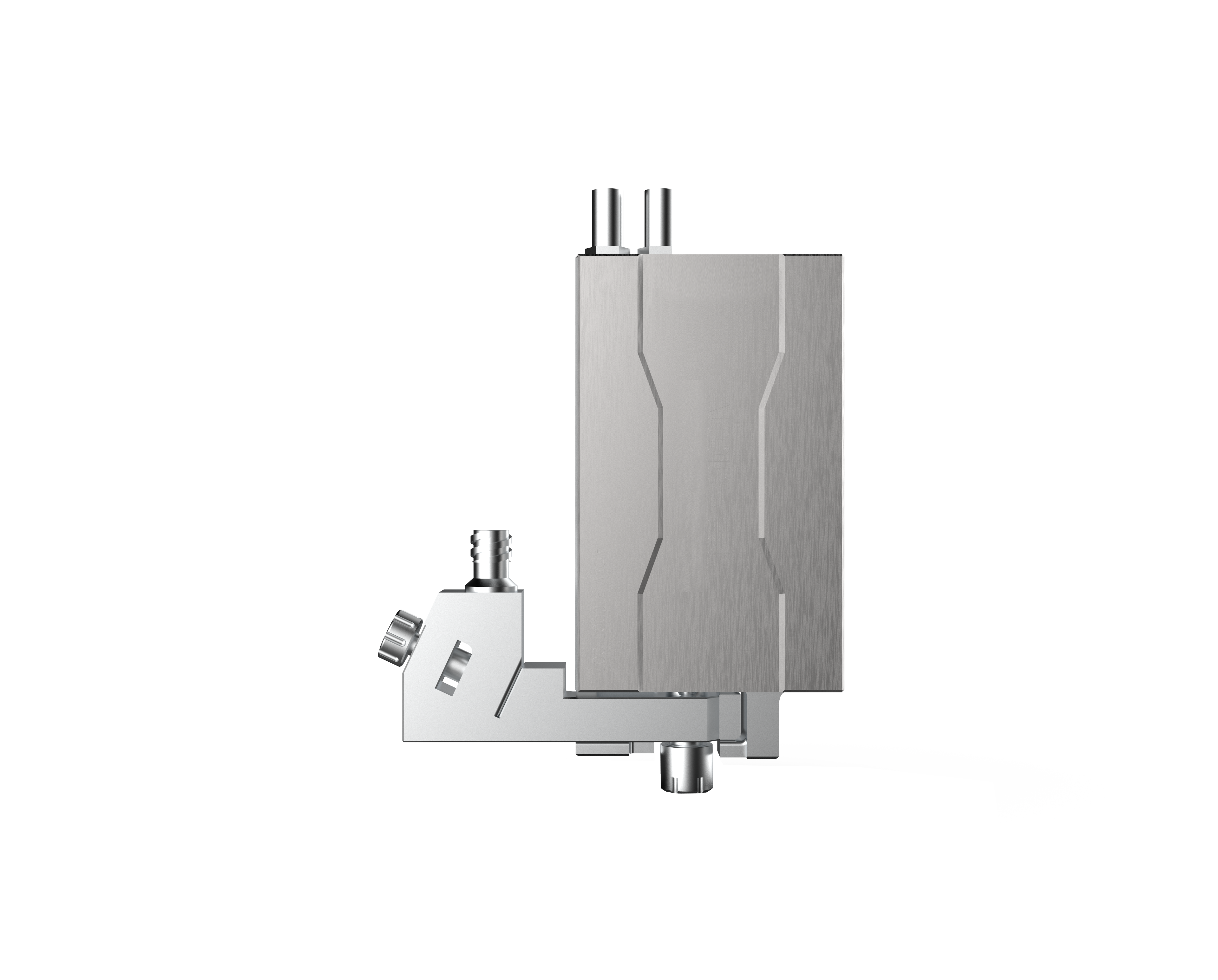

Vertical stacking structure, high product reliability

The insulating layer on the surface of the product can avoid problems such as short circuits. The longitudinal stacking structure design allows the tension to act on the entire product surface, avoiding wear and tear caused by single-point force. It can withstand high pressure and has high reliability.

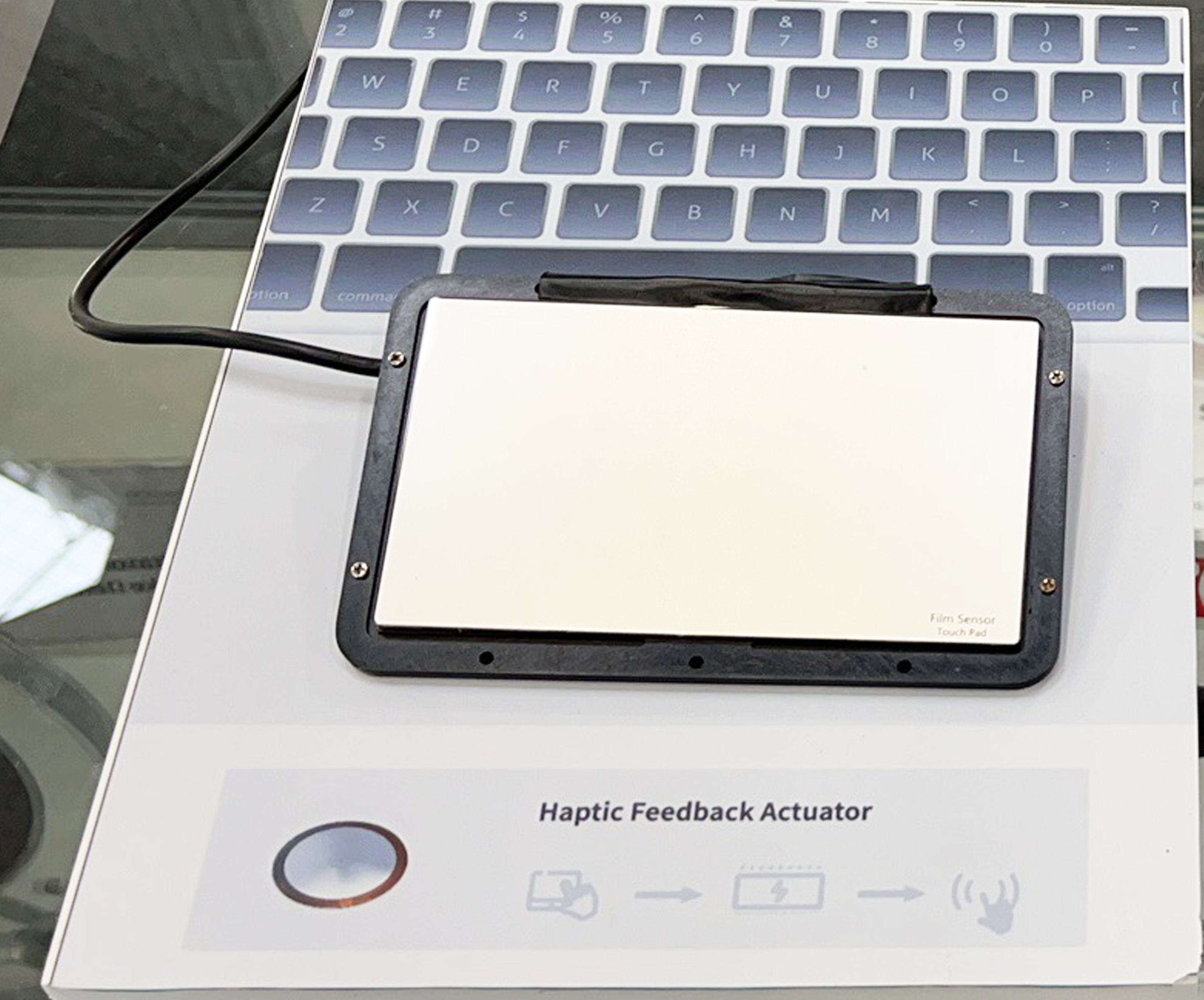

ADW's first self-developed piezoelectric dispensing valve

The piezoelectric dispensing valve independently developed by ADW is a dispensing equipment used to accurately control fluids (such as adhesives, paints, inks, etc.). The internal core actuator is deformed by the inverse piezoelectric effect after being energized, thus Push the internal valve stem, which controls the valve to achieve precise control of the fluid. Products are widely used in electronic assembly, microelectronic packaging, biomedical engineering, optical device manufacturing and other fields.

Maximum operating frequency up to 3000Hz

The continuous operating frequency of the piezoelectric dispensing valve reaches 1000Hz, and the maximum single-point operating frequency is as high as 3000Hz, which means that the device can perform up to 3000 dispensing actions per second. Such high-frequency dispensing actions can significantly improve the efficiency of the production line and ensure smooth and high-speed operation of the production process.

Minimum injection volume 1nL, high dispensing accuracy

The minimum injection volume of the piezoelectric dispensing valve is 1nL, which can achieve very small glue dot size, ensuring that the size and position of each glue dot are highly consistent; even on uneven or narrow surfaces, it can accurately dispense glue to effectively ensure the quality of the finished product, which is extremely important for application fields such as microelectronics packaging, MEMS technology, and biomedical engineering that require strict control of glue volume. On the other hand, the use of small amounts of material effectively reduces waste and reduces the procurement cost of expensive materials.

Modular design, small valve body size

The modular design of the piezoelectric dispensing valve makes it easier to integrate into the automated production line and work with other automated equipment; at the same time, each component can be quickly disassembled and assembled, which is convenient for cleaning and maintenance. The product size is small (70mm*42mm*100mm), suitable for dispensing equipment of various size requirements.

Applicable to high viscosity colloids, applicable viscosity ≤ 500,000mPa.s

The piezoelectric dispensing valve is suitable for viscosities up to 500,000mPa.s and has the ability to dispense materials with higher difficulty (such as adhesives, sealants, pastes, etc.). It is widely used in high-tech industrial fields such as electronic assembly, automobile manufacturing, medical equipment manufacturing, etc., providing more possibilities for the development of new products and innovative production processes in various applicable industries.

Click here to learn more about ADW's overseas exhibitions.

https://www.adwsensor.my/news/36.html