Ultrasonic Liquid Level Sensor exhibited at the Consumer Electronics Show (CES) in Las Vegas, USA.

Consumer Electronics Show (CES)

Dates: January 6–9, 2026

Location: Las Vegas, USA

Booth Number: North Hall 10529

Accurate and reliable liquid level measurement is a fundamental requirement across industries from water treatment to chemical processing. The Ultrasonic Liquid Level Sensor provides a sophisticated, non-contact solution designed to meet this need. By integrating multiple core functions into a single device, it offers a comprehensive system for monitoring, control, and safety.

Integrated System-on-Chip Design

Moving beyond basic sensing, this device is an integrated measurement system. It consolidates transmit drive, signal reception and acquisition, onboard signal processing, parameter storage, and communication interfaces into a compact unit. This high level of integration simplifies external circuitry, reduces installation complexity, and enhances overall system reliability. It can directly form a complete warning system with level detection and even integrate into automated filling control loops, enabling intelligent, closed-loop management of liquid storage.

Non-Contact Measurement with Container Penetration Capability

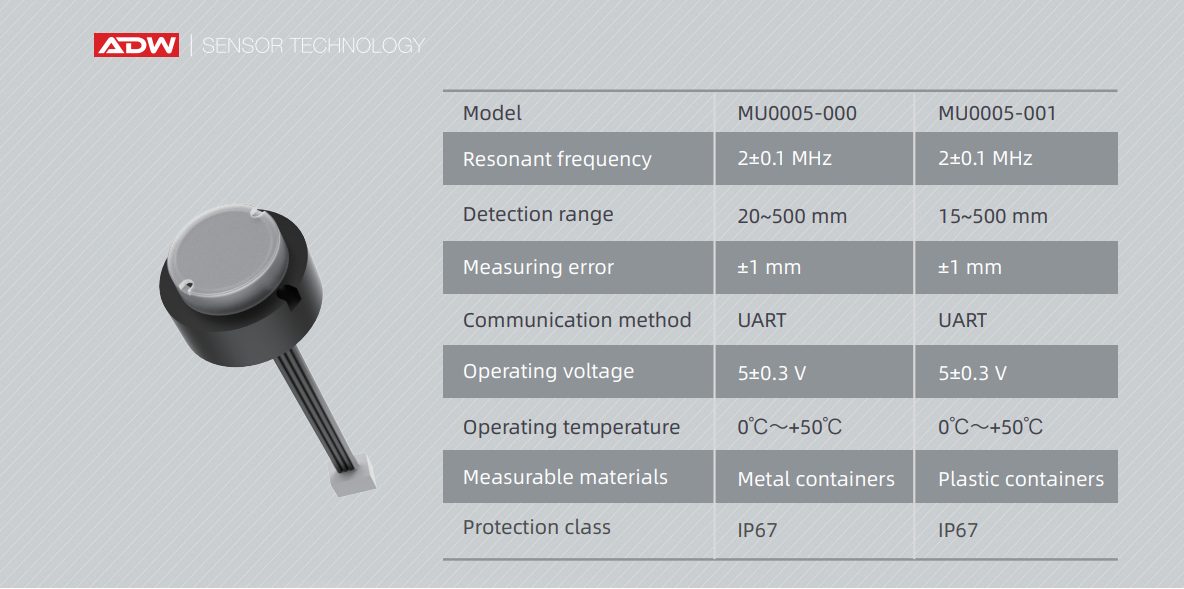

A key advantage is its ability to measure level without direct contact with the liquid. The sensor operates by emitting ultrasonic pulses that can penetrate the walls of plastic and metal containers, reflecting off the liquid surface inside. This makes it ideal for applications requiring hygienic sealing, corrosive media, or where installing an internal probe is impractical, allowing for external mounting and easy retrofitting.

Broad Application Scope and Key Features

The sensor's versatility is demonstrated by its universal liquid compatibility. It is suitable for measuring the level of a wide range of substances, including pure water, sewage, foamy liquids, oils, and various chemical solutions. This is supported by three core operational features:

Real-Time Continuous Monitoring: Provides a constant, updated data stream for process control and safety systems.

Robust Performance: The ability to handle challenging media like foam or viscous liquids ensures reliable readings in diverse conditions.

Enhanced Safety & Automation: The integrated communication and control capabilities facilitate proactive alerts and automated responses to level changes.

Conclusion

The Ultrasonic Liquid Level Sensor represents a smart, adaptable approach to level measurement. Its combination of non-invasive operation, material penetration, broad fluid compatibility, and built-in intelligence makes it an essential tool for achieving efficient, safe, and automated liquid management in industrial, commercial, and environmental applications.