In recent years, the cleaning equipment industry has seen rapid growth driven by the AIoT trend. Cleaning robots have become popular in households, malls, and outdoor spaces. However, this market boom has exposed significant imbalances in the industry. Many underperforming robot vacuum cleaners strive to integrate sweeping, suction, and mopping functions—yet often ignore actual cleaning quality. As a result, many users complain that instead of freeing their hands, these robots create more work by requiring users to clean the areas they already “cleaned.”

Among the three core functions—sweeping, suction, and mopping—mopping is the least mature in terms of technical development. It is the most prone to causing secondary cleaning issues. While users prefer robots that can mop, they are often disappointed by the performance.

Most robot vacuums use similar mopping methods. When the mopping mode is activated via an app, the water in the tank is absorbed by a cloth. This damp cloth, pressed to the floor with the robot’s weight and pressure system, rubs the surface to clean it.

But in reality, things often go wrong. Instead of relieving manual labor, these “smart” devices frequently perform poorly. Users report the robots actually make floors dirtier, prompting them to stop using the mopping feature altogether.

The same cloth is used repeatedly on the same side throughout the cleaning process. When it becomes too dirty, it stops cleaning and starts spreading dirt.

When the robot mops with a barely damp cloth, existing grime lacks sufficient moisture to be absorbed. It gets ground into the floor instead.

As the cloth dries completely, the robot transitions from wet to dry mopping. Dust gets pushed around but not removed.

Dirty cloth can be solved by simply replacing the mop cloth.

For the other two issues, there’s a smarter and more convenient solution than constantly checking the water tank: robot vacuums equipped with the ADW Water Tank Detection Module.

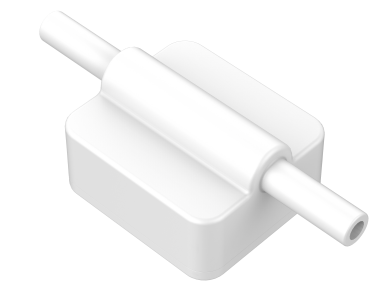

ADW’s module brings smart water tank management to robot vacuums, commercial cleaning robots, and intelligent floor cleaners. It enables real-time no-water alerts and is built from piezoelectric ceramic materials with energy conversion capabilities—helping households, malls, and campuses contribute to carbon neutrality.

Fast response: Instantly alerts when anomalies are detected

Compact design: Fits a wide range of tank sizes

Continuous monitoring: Works throughout the entire cleaning cycle

Low power consumption: Does not interfere with other components’ power needs

The ADW module is based on ultrasonic distance measurement. Since ultrasonic waves travel at different speeds in different media (faster in liquid, slower in air), the module uses echo detection to identify whether water is present in the tank.

If the water level falls below the warning threshold (indicating low water), the module instantly triggers a signal to warn of abnormal water levels.